Research & Development

R & D (Research and Development) is a crucial way to achieve future growth and maintain a relevant product portfolio in the market. Protech allocates a significant part of the resources to developing new versions of products or improving existing designs. Devoting so many years to R&D development, we now possess a robust capital, excellent technical backup, and a top-notch working team for research and development.

- Invest 10% of annual turnover in R & D;

- Own 50+ seasoned engineers in A/V Industry;

- On-site technical support provided;

- 30+ new products launched per year;

- Joint-development with Tier1 design house and semiconductor corp;

- Rapid response & fulfill customized project (normally less than 30days).

They utilized their expertise to create up 3-4 new products every month. Latest released HDMI 2.0 that boast the latest technologies. Meanwhile, our engineers can be as- signed overseas to work and complete a project with customers together.

We do extensive research before we produce any sort of new products, to ensure the highest performance and modern design. We strive to give you the best customer service available on the market, we would love to hear if you are truly satisfied with our R & D products.

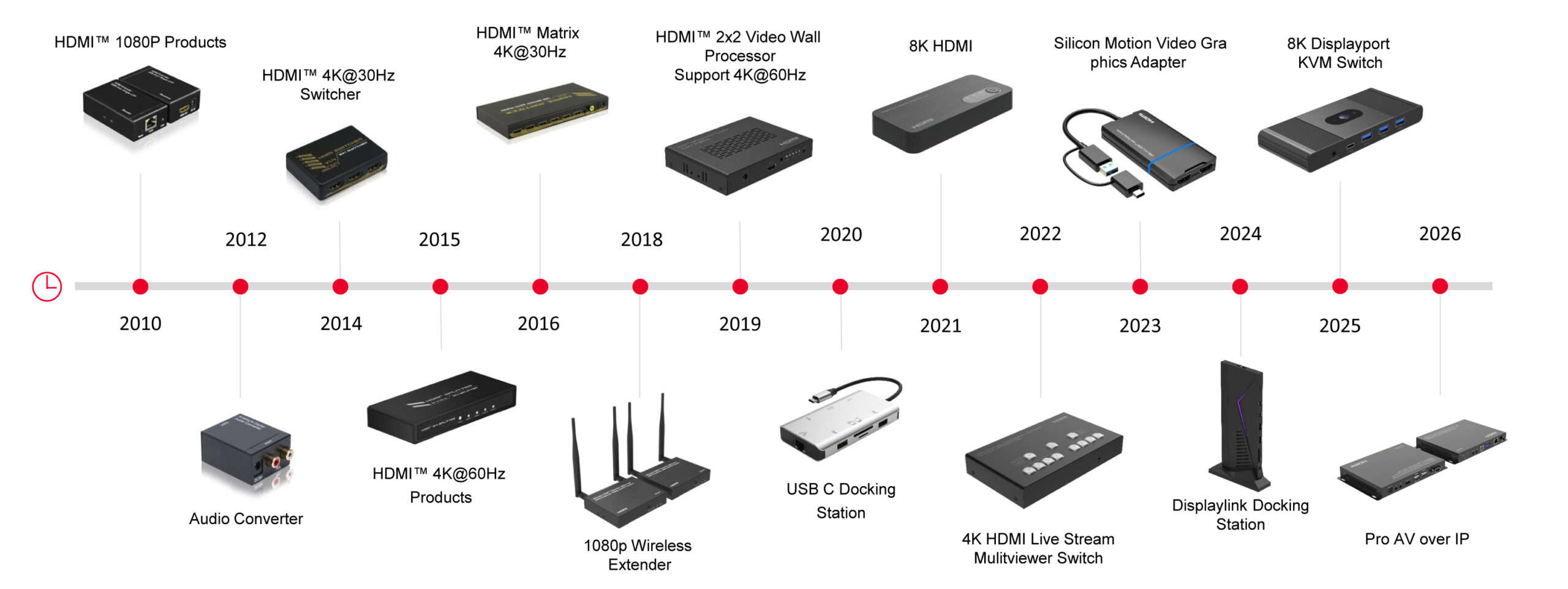

PRODUCTS ROADMAP

SMT

Customer satisfaction is our persistent pursuit , to guarantee quality and improve efficiency, one thing that must be mentioned is we introduce SMT, the abbreviation of Surface Mounting technology, is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of PCB. In the industry it has largely replaced the through-hole technology construction method of fitting com- ponents with wire leads into holes in the circuit board.

- Much higher component density and many more connections per component than the old through-hole technology;

- Small components save in weight & volume;

- Better mechanical performance under shake and vibration conditions;

- Lower defective rate, compared with those who do outward processing or those who use the old through-hole technology, we can better control the manufacturing process;

- Lower resistance and inductance at the connection; consequently, fewer unwanted RF signal effects and better and more predictable high-frequency performance;

Most importantly, the cost of the product will be lower and the lead time will be much quicker!